KHB 300

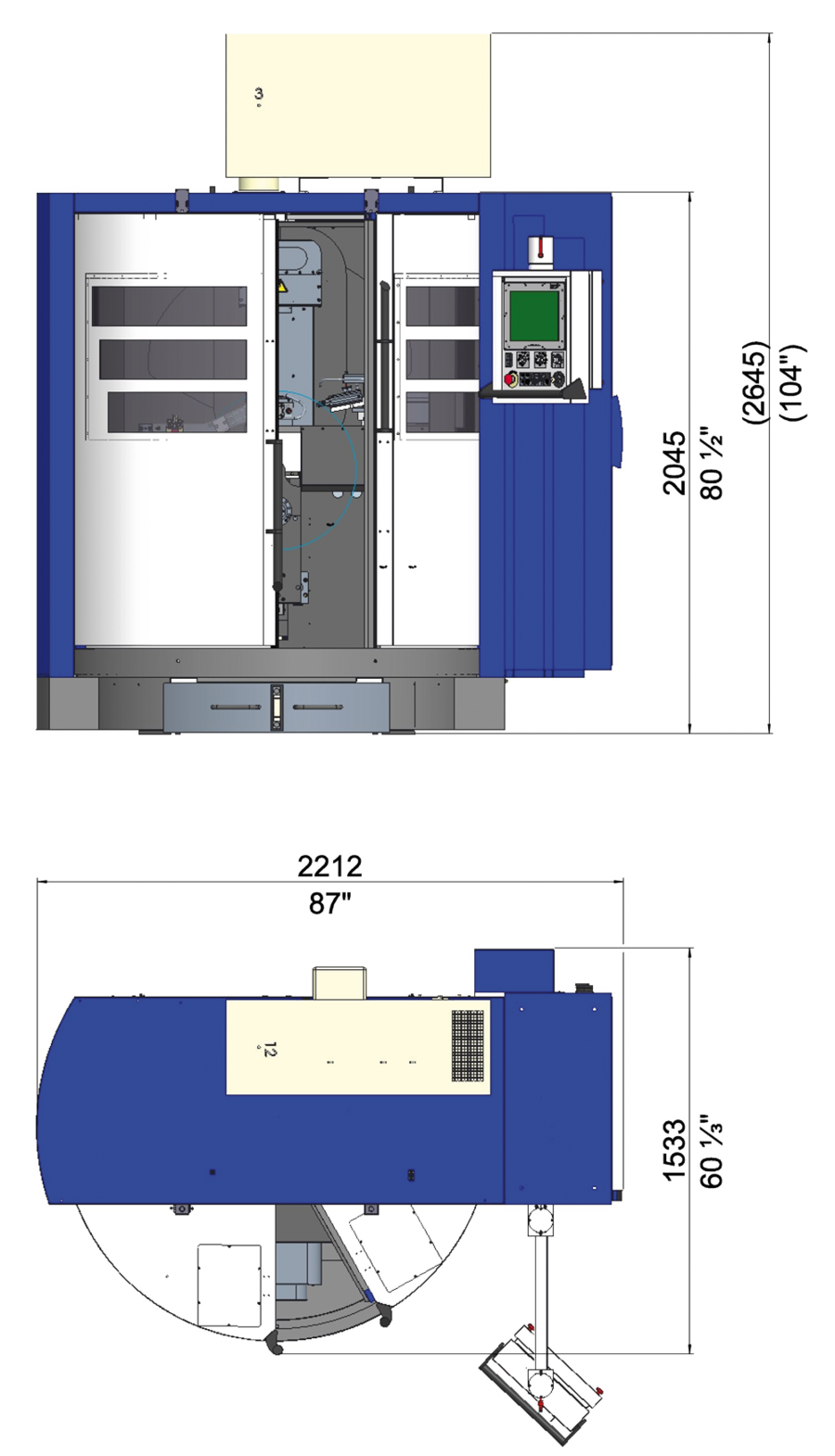

Fully automatic sharpening machine for complete machining of the hook and side angles of carbide-tipped circular saw blades [with integrated measuring system and preparation for robotization]

Highlights

- The space-saving machine concept enables for high ergonomics and excellent operability. Easy access for maintenance work on the control cabinet, coolant pump, pneumatic and extinguishing device.

- Optimal, fast and safe programming and setting of the circular saw parameters.

- "LINUX Debian 10" control with multi-core processor

- Grinding of all tooth geometries, incl. bevel and chamfering, in only one setting

- Repair tooth detection by means of measuring probe

- Measuring protocol for cutting angle, clearance angle, bevel grinding tooth back and supernatants

- After the grinding process, the concentricity is measured on the circumference and protocolled

- Preparation for the integration of a fully automatic loading system (robot)

Technical data

| Tooth geometry: | freely programmable |

| Tooth pitch: | 8* - 120* mm (*depending on tooth geometry) |

| Tooth height: | up to 40 mm |

| Saw blade thickness: | up to 8 mm |

| Tooth face rake angle: | from -25° to +30° |

| without automatic robotic loader: | |

| Circular saw outer Ø: | Ø 180 - 860 mm |

| Circular saw bore Ø: | Ø 22 - 200 mm |

| with automatic robotic loader: | |

| Circular saw outer Ø: | Ø 200 - 820 mm |

| Circular saw bore Ø: | Ø 22 - 200 mm |

| Grinding wheel outer Ø: | Ø 200 - 250 mm |

| Grinding wheel bore Ø: | Ø 32 mm |

| Grinding motor power: | 0,75 kW |

| Power requirements: | 400V 3Ph 50Hz, 6 kVA |

| Compressed air requirements: | 6 bar |

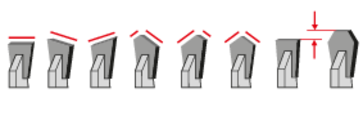

Tooth backStraight grinding

Bevel grinding up to 45° / Chamfering

Tooth height difference / triple-chip

Group toothing up to 8 teeth

Tooth backStraight grinding

Bevel grinding up to 45° / Chamfering

Tooth height difference / triple-chip

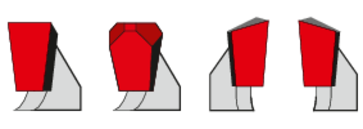

Group toothing up to 8 teeth Tooth faceStraight grinding

Bevel grinding up to 30°

Tooth faceStraight grinding

Bevel grinding up to 30°