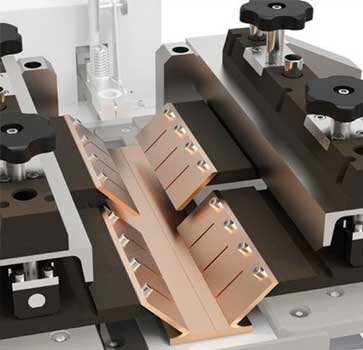

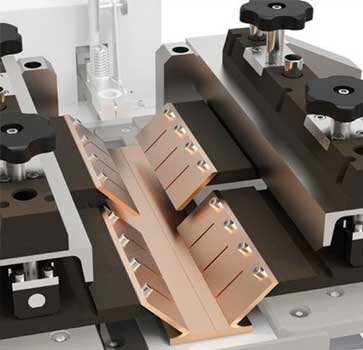

OPTIMIG was developed for welding band saw blades and consists of an electric preheating and tempering system that provides improved temperature control to avoid overheating of the steel.

To ensure uniform heating, the block is equipped with four clamping points with closing of the jaws from above for partial welds (cracks). The small heating width reduces the influence of the weld on the levelling of the saw.

Highlights

- Precise temperature measurement as close as possible to the weld seam

- Preheating and electric annealing

- 4-point clamping system for homogeneous tempering over the entire blade width

- Narrow heating width to limit the effects on the planarity

- Integraded cut-off scissors up to 240 mm of width (wider saws upon request)

- Clamping system open to the front for perfect welding of the cracks

Application programs

All-in-one-system

All-in-one-system

All-in-one-system

All-in-one-system