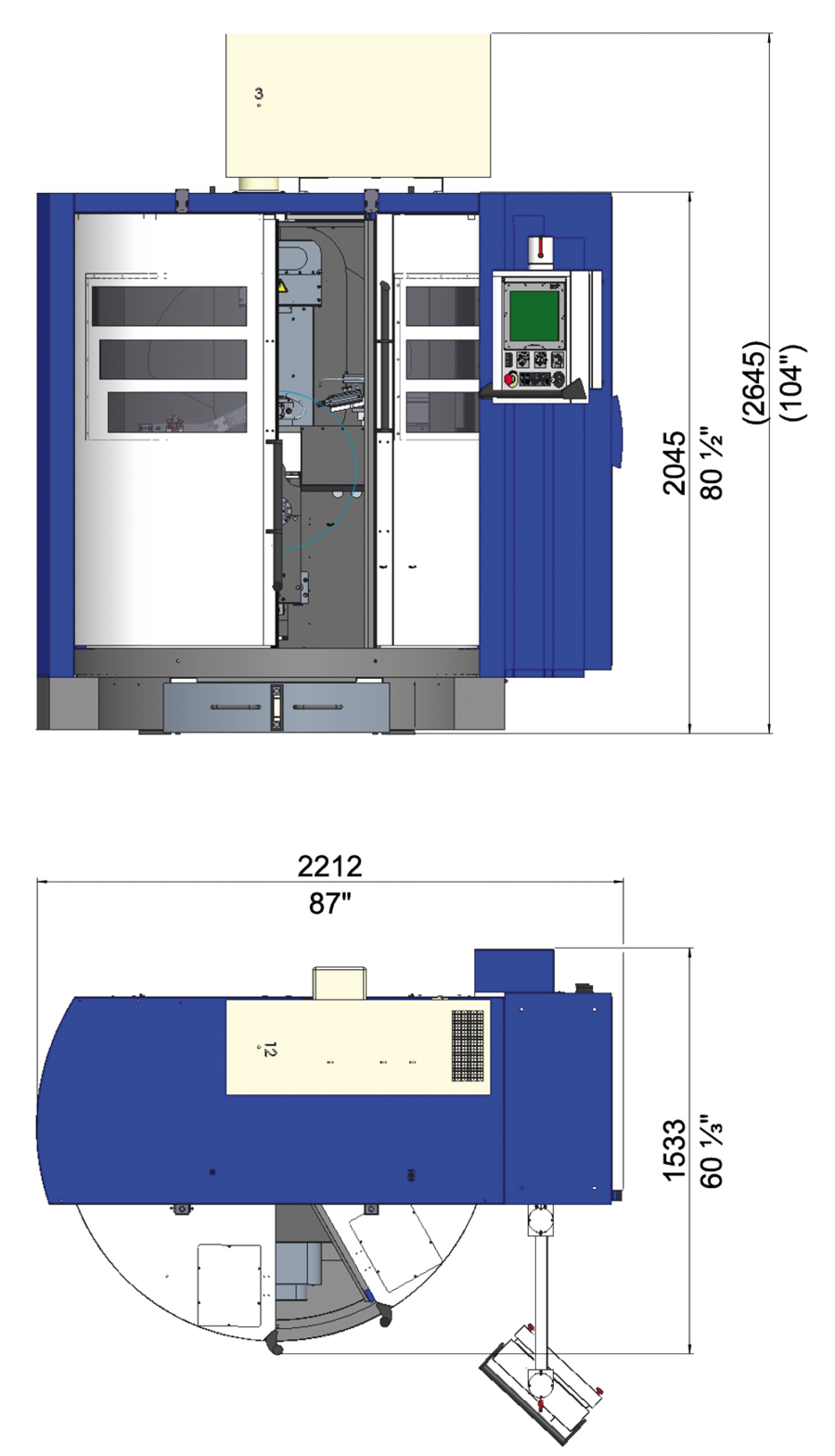

KHF 100

Fully automatic side grinding CNC machine for complete machining of the lateral angle on carbide-tipped circular saw blades

Highlights

- 6 CNC-controlled axes guarantee complete machining of all common tooth geometries in just one pass

- The space-saving machine concept allows a high degree of ergonomics and excellent operability

- Automatic adjustment of all common angles and automatic detection of the Tooth pitch with built-in sensor technology on the feed pawl

- The positioned tooth can also be finished in several passes

- Easy access for maintenance work on control cabinet, coolant pump, pneumatics and extinguishing device

- Automatic grinding wheel probing by means of acoustic sensor

- Grinding wheel compensation integrated in the basic machine

- "LINUX Debian 10" control with multi-core processor

Application programs

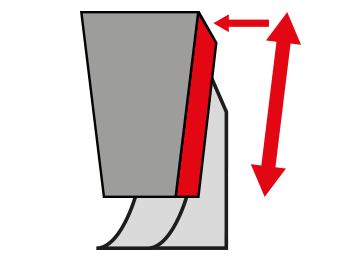

Grinding-wheel feed is at the top. This process can be repeated several times

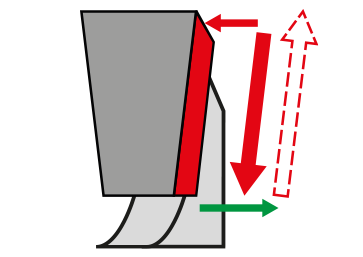

Grinding-wheel feed is at the top. This process can be repeated several times Grinding-wheel feed is at the top and at the bottom what results in 2, 4 or 6 feeds

Grinding-wheel feed is at the top and at the bottom what results in 2, 4 or 6 feeds Grinding-wheel feed is at the top. At the bottom, the grinding-wheel is moved back. The grinding head goes quickly upwards and the feed is again activated. This process can be repeated several times.

Grinding-wheel feed is at the top. At the bottom, the grinding-wheel is moved back. The grinding head goes quickly upwards and the feed is again activated. This process can be repeated several times.Technical data

| Tooth geometry: | freely programmable |

| Tooth pitch: | 10* - 120* mm (*depending on geometry) |

| Blade thickness: | up to 8 mm |

| Clearance angle tooth face: | from 0° to 5° |

| Clearance angle tooth back : | from 0° to 5° |

| Circular Saw: | Ø 180 - 860 mm |

| Circular Saw bore: | Ø 22 - 200 mm |

| optional from Ø 15 mm | |

| Cup grinding Wheel: | Ø 100 mm |

| Grinding wheel bore: | Ø 20 mm |

| Connection power: | 400V 3Ph 50Hz, 6 kVA |

| Connection air pressure: | 6 bar |