KHF 300

Fully automatic side grinding CNC machine for complete machining of the side angles of carbide-tipped circular saw blades [with integrated measuring system and preparation for robotization]

Highlights

- Conceived and designed for the fully automatic processing of carbide-tipped circular saws

- Blade feed from right to left, including radius tracking

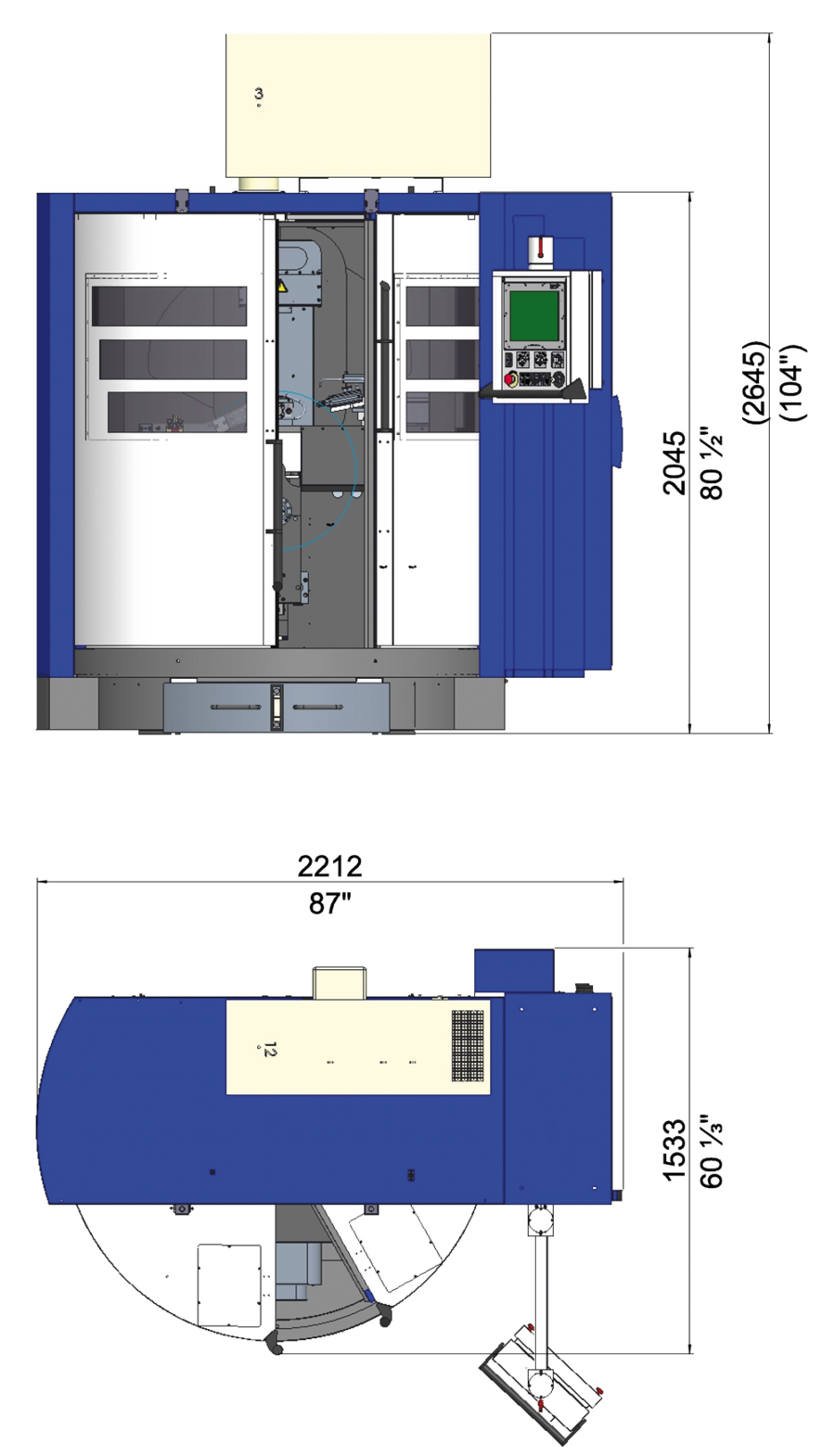

- The space-saving machine design allows for high ergonomics and excellent usability

- Easy access for maintenance work to the electrical cabinet, coolant pump, pneumatics and extinguishing systems

- Unlimited storage for circular saw parameters

- Optimal, fast and safe programming and setup of circular saw parameters

- The positioned tooth can also be ground completely in several passes.

- Manual or automatic (using a probe) repairment tooth recognition

- Measurement protocol of the side clearance and centricity offset

- Ready for the integration of a fully automatic loading system (robot)

Technical data

| Zahngeometrie: | frei programmierbar |

| Zahnteilung: | 10* - 120* mm (*je nach Blattparameter) |

| Blattstärke: | bis 8 mm |

| Zahnbrust Freiwinkel: | 0° bis 5° |

| Zahnrücken Freiwinkel: | 0° bis 5° |

| Kreissägen Ø: | Ø 180 - 860 mm (ohne Roboter) |

| Ø 200 - 820 mm (mit Roboter) | |

| Kreissägen-Bohrung Ø: | Ø 22 - 200 mm |

| optional ab Ø 15 mm | |

| Topfschleifscheibe Ø: | Ø 100 mm |

| Schleifscheiben-Bohrung Ø: | Ø 20 mm |

| Anschluss elektrisch: | 400V 3Ph 50Hz, 6 kVA |

| Anschluss Druckluft: | 6 bar |

ModesSymmetrical grinding starting from the center of the blade body

Grinding based on automatic setting of tool zero points

Grinding based on manual setting of tool zero points

ModesSymmetrical grinding starting from the center of the blade body

Grinding based on automatic setting of tool zero points

Grinding based on manual setting of tool zero points