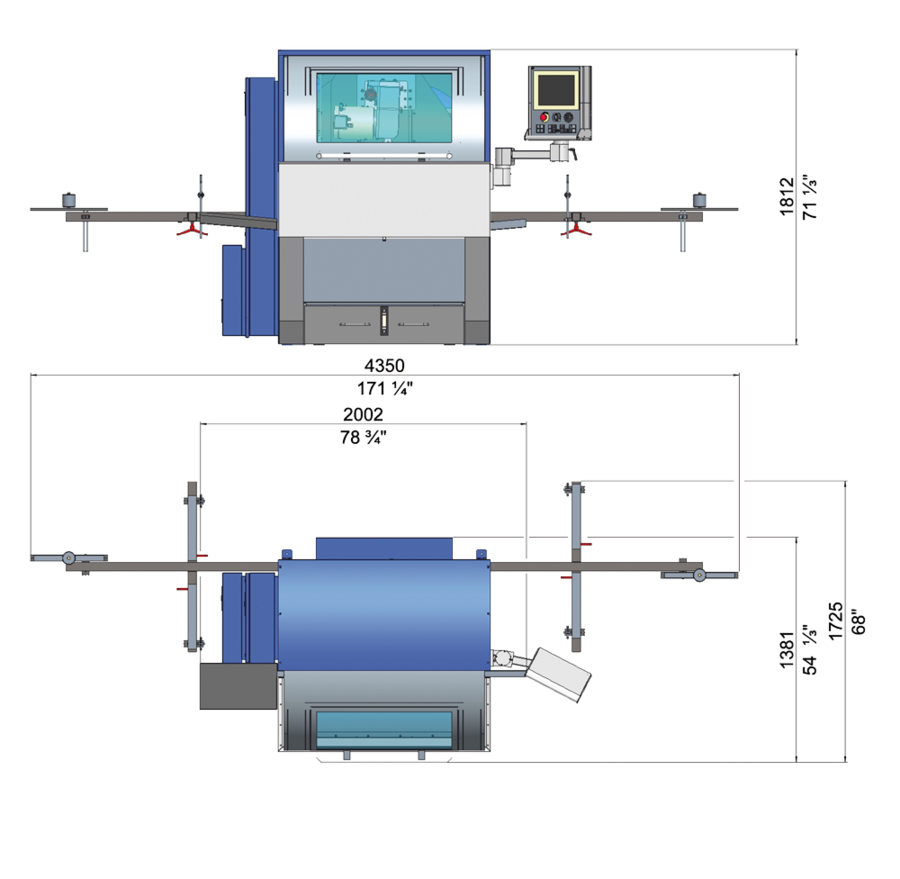

BNP 200 [G2]

Fully automatic profile sharpening machine for band saw blades controlled with 4 CNC axes

![BNP 200 [G2]](/fileadmin/user_upload/Maschinen/Produkte/bnp_200.png)

Highlights

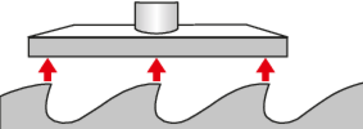

- Profile-grinding of standard and Stellite-tipped band saw blades

- by means of CNC axes "X" & "Y" (several complete cycles of the band saw blade)

- by means of CNC axes "W" & "Y" (grinding of the positioned and clamped saw tooth)

- Top/Face-grinding of Stellite- and Carbide-tipped band saw blades

- by means of CNC axes "W" & "Y" (grinding of the positioned and clamped saw tooth)

- Automatic set up of the saw

- Positioning the saw to the workpiece grinding position (automatic)

- Positioning the saw to the workpiece change position (automatic)

- Automatic recognition of the tooth group and measurement of the tooth pitch

- CNC controlled cutting angle Adjustment ("S" axis)

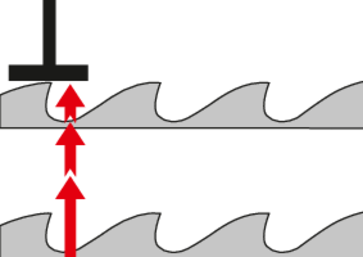

- Automatic probing of the grinding wheel at the saw tooth

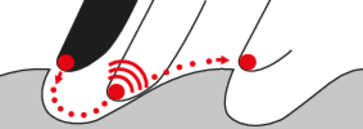

- Automatic tooth shape tracing "Tooth Tracing System - TTS"

Application programs

Grinding of standard tooth forms Grinding of variable tooth forms

Grinding of standard tooth forms Grinding of variable tooth forms Alternating grinding on the tooth face and back

Alternating grinding on the tooth face and back Automatic probing of the tool zero point with acoustic sensor

Automatic probing of the tool zero point with acoustic sensor Grinding the winter tooth

Grinding the winter tooth Automatic setup of the saws

Automatic setup of the saws Automatic tooth shape tracing "Tooth Tracing System"

Automatic tooth shape tracing "Tooth Tracing System" Variable height measurement with Analogue sensor

Variable height measurement with Analogue sensorTechnical data

| Tooth shape: | freely programmable |

| Tooth pitch: | 10 - 100 mm |

| Tooth height: | up to 30 mm |

| Front rake angle: | 0° - 35° |

| Blade width standard: | 75 - 360 mm |

| Blade width option: | 30 - 360 mm |

| Blade length standard: | from 5'300 mm |

| Blade length option: | from 4'300 mm |

| Blade thickness: | 0.6 - 3.0 mm |

| Grinding wheel: | Ø 350 mm |

| Grinding wheel bore: | Ø 32 mm |

| Grinding wheel motor: | 2,2 kW |

| Power requirement: | 400V 3Ph N, 50Hz, 3,6kVA |

| Air connection: | 6 bar |

| Coolant tank: | 170 l |