BNA 100

Fully automatic Stellite tipping machine for equipping of the saw teeth by plasma welding process

Highlights

- Encapsulated machine - welding fumes can be extracted

- Stable and centred machine design. Robust, precise and low-vibration

- Simplest repair of broken teeth

- Annealing of the welded joint with the torch or optionally with a high-frequency annealing device

Stelliting machine using the plasma welding process:

- Secure, homogeneous connection with the parent material

- Shorter grinding times / lower grinding wheel consumption

- Use of low-cost stellite

- Higher stelliting speed

- Highest economic efficiency

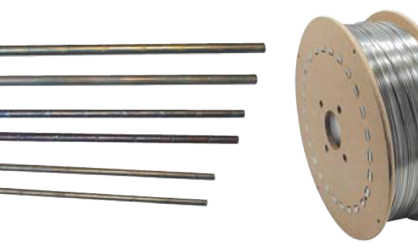

- Designed for rod as well as wire stellite

Application programs

Stellited tooth in plasma welding process

Stellited tooth in plasma welding process Stellited tooth in resistance welding process

Stellited tooth in resistance welding processTechnical data

| Band Saws | |

| Tooth pitch: | 10 - 100 mm |

| Blade length: | from 6'000 mm |

| Blade width "Standard": | 75 - 340 mm |

| Blade width "Option": | 35 - 290 mm |

| Blade thickness: | from 0,6 mm |

| Circular Saws | |

| Tooth pitch: | 10 - 40 mm |

| Diameter Ø: | Ø 220 - 900 mm |

| Bore Ø: | Ø 20 - 240 mm |

| Blade thickness: | 1.0 - 6.0 mm |

| Gang / Frame Saws: | |

| Tooth pitch: | 10 - 100 mm |

| Blade length (overall): | from 800 mm (minimum) |

| Blade length (toothed area): | up to 1800 mm (maximum) |

| Blade width: | 80 - 240 mm |

| Blade thickness: | from 1.6 mm |

| Hook angle: | from 10° to 40° |

| Connection load without annealing: | 6,3 kVA / 5,0 kW |

| Connection load with annealing: | 8,5 kVA / 7,1 kW |

| Compressed air: | 6 bar, 30 l/min |

| Weight: | approx. 1350 kg |