SAA

Fully automatic stellite tipping machine for equipping of the saw teeth by resistance welding process

Highlights

- The structure of the stellite is not changed during welding, therefore no cracks or holes occur in the stellite

- No tooth tips need to be cut before stelliting. If the saws are stellited repeatedly, the residual stellite does not have to be grinded away.

- The loading of band saws is fully automatic. These are annealed in the same annealed via high frequency in the same operation.

- The machine is equipped with a programmable control, which ensures very easy operation of the machine

- No expert is required

- The hydraulic control makes it possible to set each working speed individually set

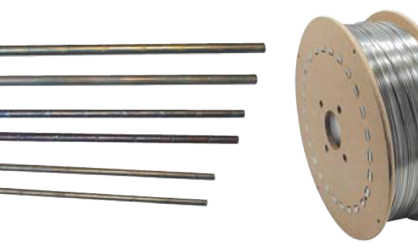

- The stellite is welded in vertically and can be adjusted in length from 4 - 10 mm. can be adjusted

- With the same machine, band, circular and gang saws can be stellited by simple can be set up by simple retooling

Technical data

| Blade thickness: | 0,8 - 3,2 mm |

| Band saw | |

| Tooth pitch: | 13 - 115 mm |

| Blade length standard: | from 5'500 mm |

| Blade length optional: | from 4'700 mm |

| Blade width standard: | 80 - 360 mm (70 mm bis Zahngrund) |

| Blade width optional: | from 25 mm |

| Circular saw | |

| Diameter: | Ø 250 – 1200 mm |

| Bore: | Ø 22 - 210 mm |

| Gang / Frame saw | |

| Toothed length: | up to 1500 mm |

| Blade width: | 80 – 180 mm |

Stellited tooth in plasma welding process

Stellited tooth in plasma welding process Stellited tooth in resistance welding process

Stellited tooth in resistance welding process