STA

Fully automatic, hydraulic controlled swaging machine for band and gang saw blades

Highlights

- The ISELI STA has a robust steel design. The machine is hydraulically controlled and equipped for band saws.

- The same tooth can be swaged once or twice and shaped in a single pass

- All the work processes are hydraulically controlled

- The blade feed is effected by the swage die so that accurate positioning of the saw tooth is guaranteed

- Swaging densifies the tooth point of the saw tooth of what results in a smoother and more accurate cut of the wood and a higher production

- By swaging, the tooth tip of the saw tooth is compressed, thus achieving a longer working life

- The swaging excenter is mounted on both sides and can be moved axially. It can be used in 10 different positions

- The clearance- and the rake angle, the width to be shaped and the tooth pitch are easily set according to scales, without changing any machinery parts

Technical data

| Tooth pitch: | 18 - 76 mm |

| Tooth height: | from 10 mm |

| Clearance angle: | 5 - 28° |

| Front rake angle: | 5° - 35° |

| Shaping fences-clearance angle: | 5 or 8° |

| Band saw blades | |

| Blade width standard: | 80 - 360 mm (standard) |

| from 50 mm (option) | |

| Blade length: | from 5'300 mm |

| Gang / frame saw blades | |

| Toothed length: | up to 1'500 mm |

| Blade width: | 75 - 180 mm |

| Working speed: | up to 6 t/min. |

| Power requirements: | 400V 3Ph N, 50Hz, 3,0kVA |

| Air connection: | 6 bar (only for automatic lubrication) |

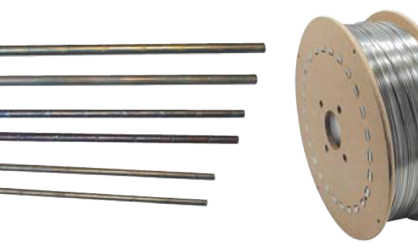

Swaged Tooth

Swaged Tooth Swaged Tooth Shaped

Swaged Tooth Shaped Swaged Tooth Grinded

Swaged Tooth Grinded